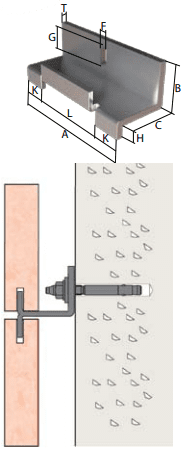

L-Bracket (Standard & Serrated) | Type ST- 1600 500 Double Up and Down

L-Bracket (Standard & Serrated) Double Up and Down | Type ST- 1600 500

L-Bracket (Standard & Serrated) Double Up and Down,Materials SS304, SS316, SS316L, SS316TI, The support and restraint brackets are Fixed using expansion anchors, chemical anchors, etc. Using expansion bolts, an installation of the facade is also possible during the winter months. Due to the small drill hole dimensions of the expansion bolts, the facade can be installed very quickly.

Providing high quality Structural Components and Facade Cladding Fixings for the Construction Industry

high Quality facade Fixings

Custom fixings fabricated on-demand

Natural Stone Fixing Systems.

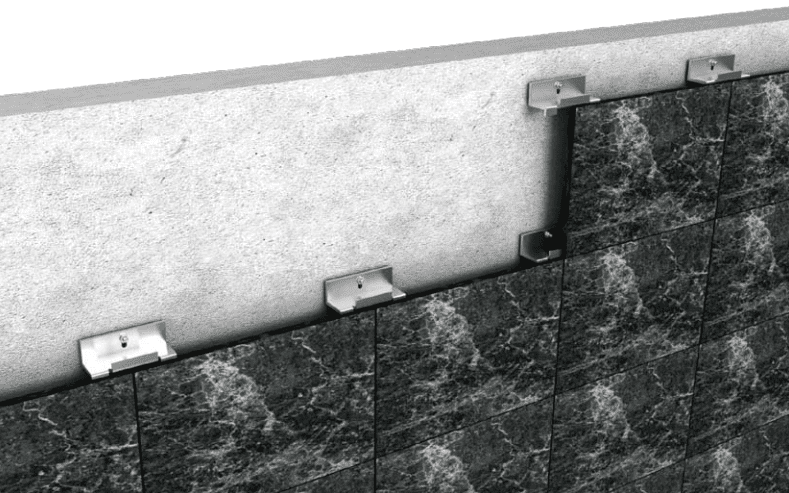

Marble and Granite Mechanical Cladding Systems

Types Of Fixings

Principles for the Fixing of Building Cladding

The fixing systems for building cladding are composed of several elements (angles, expansion bolts, screws, nuts, washers, etc), each of which shall present the appropriate mechanical features in respect to the requirements posed by the specific project.

Any type of cladding, once fixed, is subject to two primary types of load:

– Permanent load (the dead load), due to the weight of the cladding itself.

– Variable load (applied loads), due to the wind, thermal expansions, seismic motions, etc.

Types of Facade Building Substructure

1- Stone fixed to concrete wall

2- Stone fixed to hollow block wall

3- Stone fixed to solid block

4- Stone fixed to composite substructure

Stone Cladding System, Granite Anchor, Marble Clamp, Z Bracket, Z Fixing System is Lifting and Handling Tools from China, welcome to buy Stone Cladding System Granite Anchor, Marble Clamp Z Bracket Z Fixing System with good quality and price from China suppliers and manufacturers directly.

Heavy Duty Anchor,fixing system,is used for fixing panels of granite, marble, sandstone, limestone, travertine, crystall glass, ceramic, calcium silicate, concrete fiber board, etc, in wall cladding projects.

Standard items:

| Item No. | T (mm) | A (mm) | B (mm) | C (mm) | H (mm) | L (mm) | K (mm) | Slot (mm) | |

| 120.50.30.3-1605 | 3 | 120 | 50 | 30 | 15 | A/2 | A/4 | 8.5 x 22 | |

| 120.50.35.3-1605 | 3 | 120 | 50 | 35 | 15 | A/2 | A/4 | 8.5 x 22 | |

| 120.50.40.3-1605 | 3 | 120 | 50 | 40 | 15 | A/2 | A/4 | 8.5 x 22 | |

| 140.60.30.3-1605 | 3 | 140 | 60 | 30 | 15 | A/2 | A/4 | 8.5 x 22 | |

| 140.50.45.3-1605 | 3 | 140 | 50 | 45 | 15 | A/2 | A/4 | 8.5 x 22 | |

| 120.60.30.4-1605 | 4 | 120 | 60 | 30 | 15 | A/2 | A/4 | 8.5 x 22 | |

| 120.60.35.4-1605 | 4 | 120 | 60 | 35 | 15 | A/2 | A/4 | 8.5 x 22 | |

| 120.50.40.4-1605 | 4 | 120 | 50 | 40 | 15 | A/2 | A/4 | 10.5 x 22 | |

| 120.50.45.4-1605 | 4 | 120 | 50 | 45 | 15 | A/2 | A/4 | 10.5 x 22 | |

| 120.50.50.4-1605 | 4 | 120 | 50 | 50 | 15 | A/2 | A/4 | 8.5 x 22 | |

| 120.60.50.4-1605 | 4 | 120 | 60 | 50 | 15 | A/2 | A/4 | 10.5 x 22 | |

| 140.60.50.4-1605 | 4 | 140 | 60 | 50 | 15 | A/2 | A/4 | 10.5 x 22 | |