Applications of Hastelloy C-276 Fasteners in the Chemical Processing Industry

Introduction

In chemical processing environments, where equipment is constantly exposed to highly corrosive substances, material selection becomes critical for operational safety and longevity. Fasteners are no exception. Choosing the right fastening materials can prevent costly downtime, structural failures, and safety hazards.

Hastelloy C-276, a nickel-molybdenum-chromium alloy, is one of the premier choices for manufacturing fasteners designed to endure aggressive chemical conditions. This article explores why Hastelloy C-276 fasteners are indispensable for chemical processing industries and how they outperform standard stainless steel solutions.

What Makes Hastelloy C-276 Ideal for Chemical Processing?

Hastelloy C-276 is renowned for its outstanding corrosion resistance across a wide range of aggressive environments. Its chemical composition — high nickel, molybdenum, chromium, and a small amount of iron — enables it to withstand:

Strong oxidizers and reducers

Chloride-induced pitting and crevice corrosion

Sulfuric, hydrochloric, and nitric acids

Wet chlorine gas and chlorine dioxide

Unlike traditional stainless steel fasteners, Hastelloy C-276 fasteners maintain structural integrity even under fluctuating temperatures and highly acidic conditions. Their low carbon content further minimizes the risk of carbide precipitation during welding, ensuring reliable performance in welded assemblies.

Key Applications of Hastelloy C-276 Fasteners

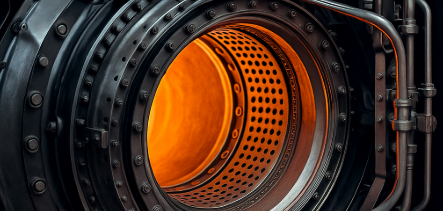

1. Chemical Processing Plants

In facilities handling aggressive chemicals such as sulfuric acid, hydrochloric acid, and chlorine compounds, standard stainless steels often fail over time. Hastelloy C-276 fasteners, however, offer long-term corrosion resistance, maintaining mechanical strength and securing critical joints.

Typical applications include:

Heat exchangers

Reactors

Evaporators

Storage tanks

2. Pulp and Paper Industry

Processes involving chlorine dioxide bleaching and chemical pulping expose equipment to harsh corrosive agents. Hastelloy C-276 bolts, nuts, and washers provide durable fastening solutions for digesters, bleach plants, and chemical recovery systems.

3. Pollution Control Systems

Scrubbers, stack gas scrubbers, and flue-gas desulfurization units (FGD) operate in chemically aggressive atmospheres. Using Hastelloy C-276 fasteners ensures longevity and reduces maintenance frequency in emission control systems.

4. Waste Treatment Facilities

Industrial waste often contains aggressive acids and salts. Fasteners made from Hastelloy C-276 are commonly employed in equipment exposed to acidic leachates, thereby enhancing facility durability and safety.

Recommended Grades and Forms

At Wisine Fasteners & Metal Supply, we provide Hastelloy C-276 fasteners in various forms, including:

Hex bolts and heavy hex bolts

Nuts and locknuts

Washers and flat washers

Stud bolts and threaded rods

Customized non-standard fasteners

All our products comply with international standards such as ASTM B574, B575, and B564, ensuring maximum reliability for critical applications.

Conclusion

When it comes to corrosive chemical environments, standard fasteners simply cannot match the performance of Hastelloy C-276 fasteners. Their unparalleled corrosion resistance, mechanical strength, and reliability make them the material of choice for the chemical processing, pulp and paper, pollution control, and waste treatment industries.

At Wisine Fasteners & Metal Supply, we specialize in supplying certified Hastelloy C-276 fasteners customized to your exact specifications. Our products are trusted by clients worldwide for their superior quality and performance.